SOLUTION BRIEF: MACHINE MONITORING APPLICATIONS IN THE OIL AND GAS INDUSTRY

Add Time:2018-11-21

View Count:4642

Resoure:EPC

Application Study - Machine Health Monitoring

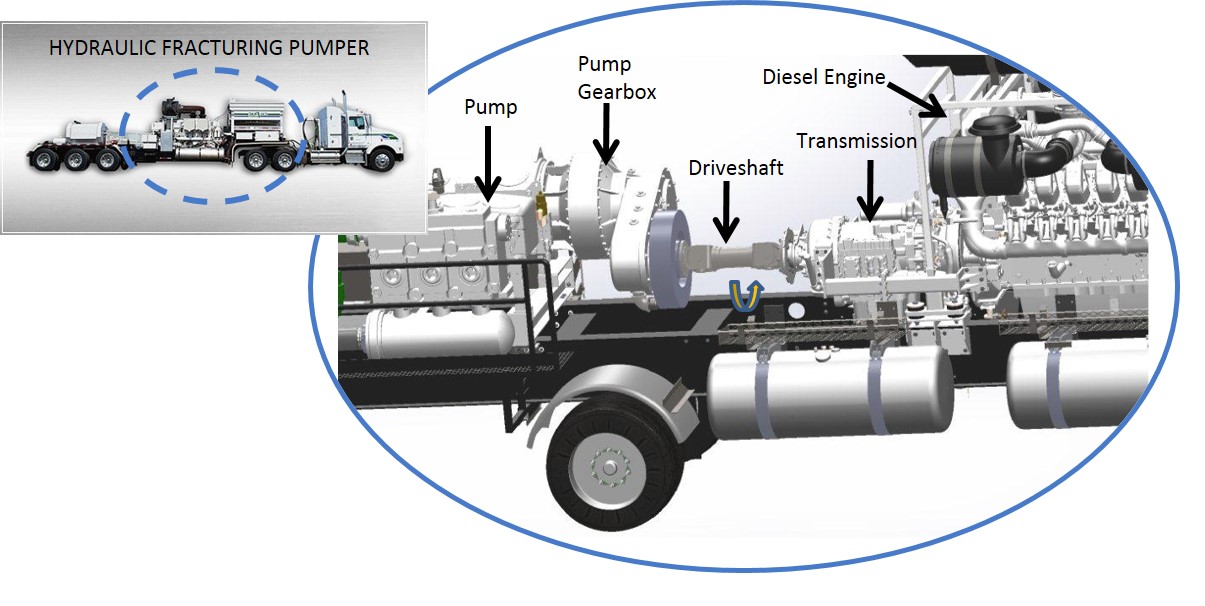

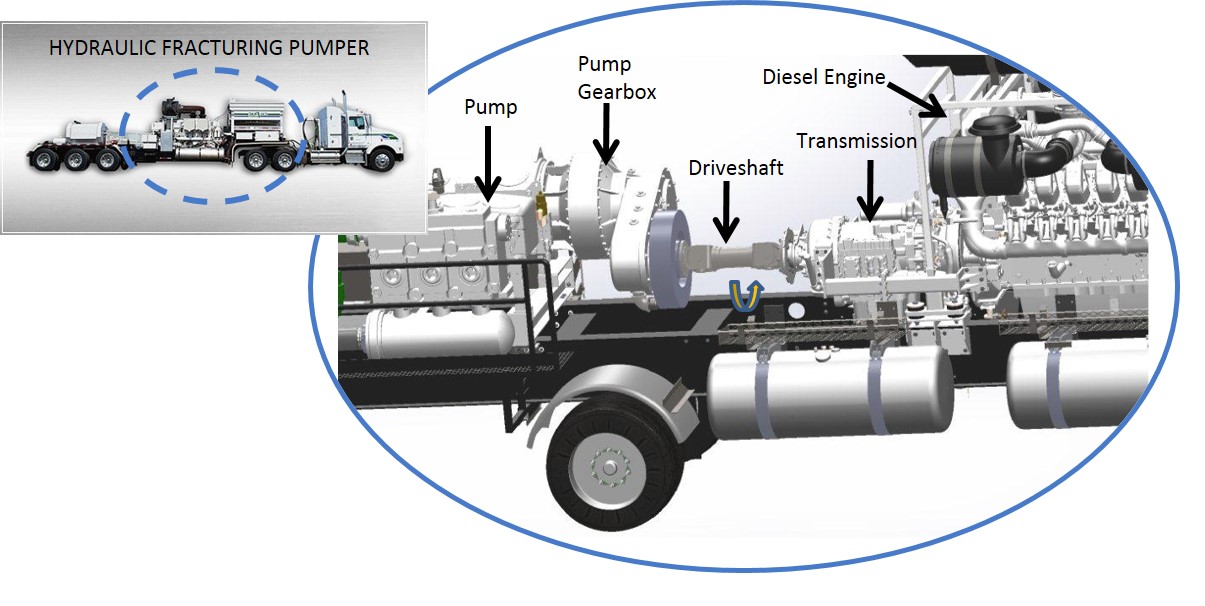

Reducing unplanned downtime in the oil and gas industry: use of the SensorCloud™ platform allows operators to characterize machine fatigue, perform predictive analysis, improve system design, and setup monitoring of real-time operating conditions.

Rigorous use conditions - Oil and gas rigs operate in complex vibration environments. Characterizing and predicting failure of major components is key in reducing project cost and downtime.

Solution

Use a wireless sensor network with SensorCloud to monitor equipment condition and anticipate failures.

Connect: Deploy the SensorCloud platform in conjunction with wireless torque, pressure, and temperature sensors to collect new rig performance metrics alongside existing process data. Leverage existing technical expertise to provide timely analysis of truck conditions.

Monitor: Keep distributed teams informed of equipment performance anomalies and trends that warrant replacement planning with real-time SMS and email alerts.

Analyze: Use SensorCloud's embedded MathEngine® analytics tool to unlock business value from historical performance logs. Determine which equipment vendors provided the best return on investment (ROI) and the lowest total cost of ownership. Optimize machine target set points to minimize costs and maximize life.

Machine Monitoring Benefits

-

Reduce unplanned downtime and improve safety

-

Make informed equipment purchases & maximize ROI

-

Optimize machine performance and lifetime

Challenge

Anticipating equipment failures in the oil and gas industry is crucial for managing bottom line operational expenses. Existing methods for collecting and analyzing rig performance data are often inadequate for extracting business value and real-time actionable insights:

-

Manual machine-hour log collection is time-intensive and error-prone

-

It is difficult to unify sensor and process data using different equipment from multiple vendors

-

Analytics packages and associated expertise are typically expensive

Live performance monitoring - With SensorCloud monitoring, equipment performance can be tracked during operation for failure conditions . Data can be analyzed further for predictive modeling.

Features

-

Scalable big-data visualization & real-time SMS and email alerting

-

Ultra-reliable & secure data archival

-

Flexible and programmable data analytics

-

White-label branding, embeddable widgets & custom portals

Enquiry:hkmarketing@epc.com.hk

Enquiry:hkmarketing@epc.com.hk  Whatsapp Enquiry: +85261990717

Whatsapp Enquiry: +85261990717