Introduction of the Test Method for Evaluating Thermal Runway Fire Propagation in Battery Energy Storage Systems

FTT UL 9540A Test

FTT supplies and installs the UL 9540A and trains clients in its use. FTT can also supply any specific components to clients wishing to part design and build their own equipment.

The UL 9540A standard has been developed to test battery energy storage systems in different scales:

? Cell level

? Module level

? Unit level

? Installation level

The Cell Level Test

The cell level test involves heating up a battery cell to initiate thermal runaway. Flexible film heaters are applied to the external of a battery and connected to a temperature controller. The Cell Level Test primarily uses analytical chemistry apparatus and is not a reaction-to-fire test. Consequently, clients source this apparatus themselves so it is not offered by FTT.

The Module Level Test

The module level test involves heating up several cells in a battery module to initiate thermal runaway and collecting the gaseous products under a hood and exhaust system with an internal diameter of 400 mm. A sample of the exhaust gas is taken to measure the concentration of oxygen, carbon dioxide, carbon monoxide, hydrocarbons and hydrogen as well as the composition of additional gases using FTIR. In addition the concentration of smoke in the exhaust is measured using a white light smoke measurement system. These measurements enable, among others, the heat release to be determined by the technique known as oxygen consumption calorimetry and smoke production rates to be determined by the FTT Calorimetry software (BatteryCalc).

There are several parts to the Module Level test setup:

? Extraction system

? Weighing system

? Thermal runaway initiation system

? Temperature measurement system

? Heat release and smoke production instrumentation

? Instrumentation to calibrate the heat release rate system

? Additional gas measurements

? Data acquisition and analysis software

The Unit Level Test

The testing principle from the module level test can be applied to the unit level test measuring fires up to 10MW by increasing the hood size, exhaust diameter and exhaust flow rate, as explained in ISO 24473, Open Calorimetry – Measurement of the rate of production of heat and combustion products for fires up to 40MW.

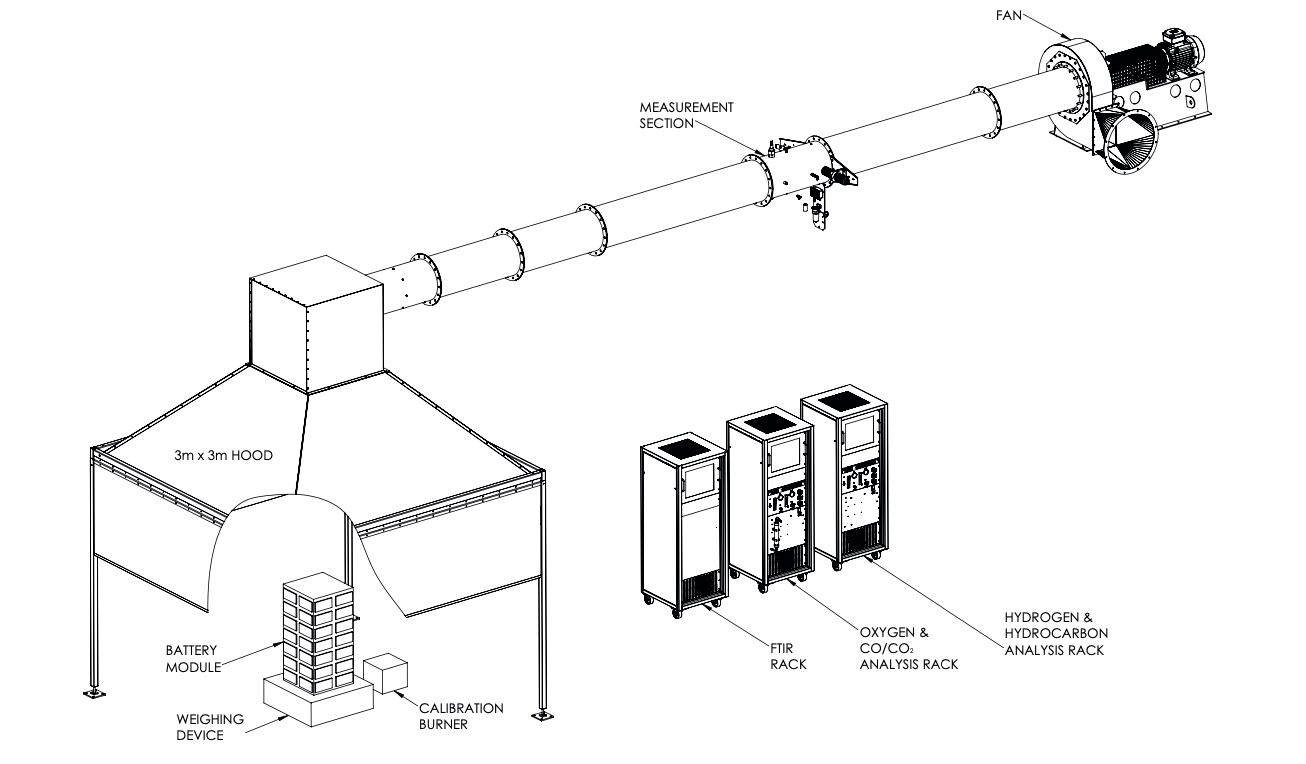

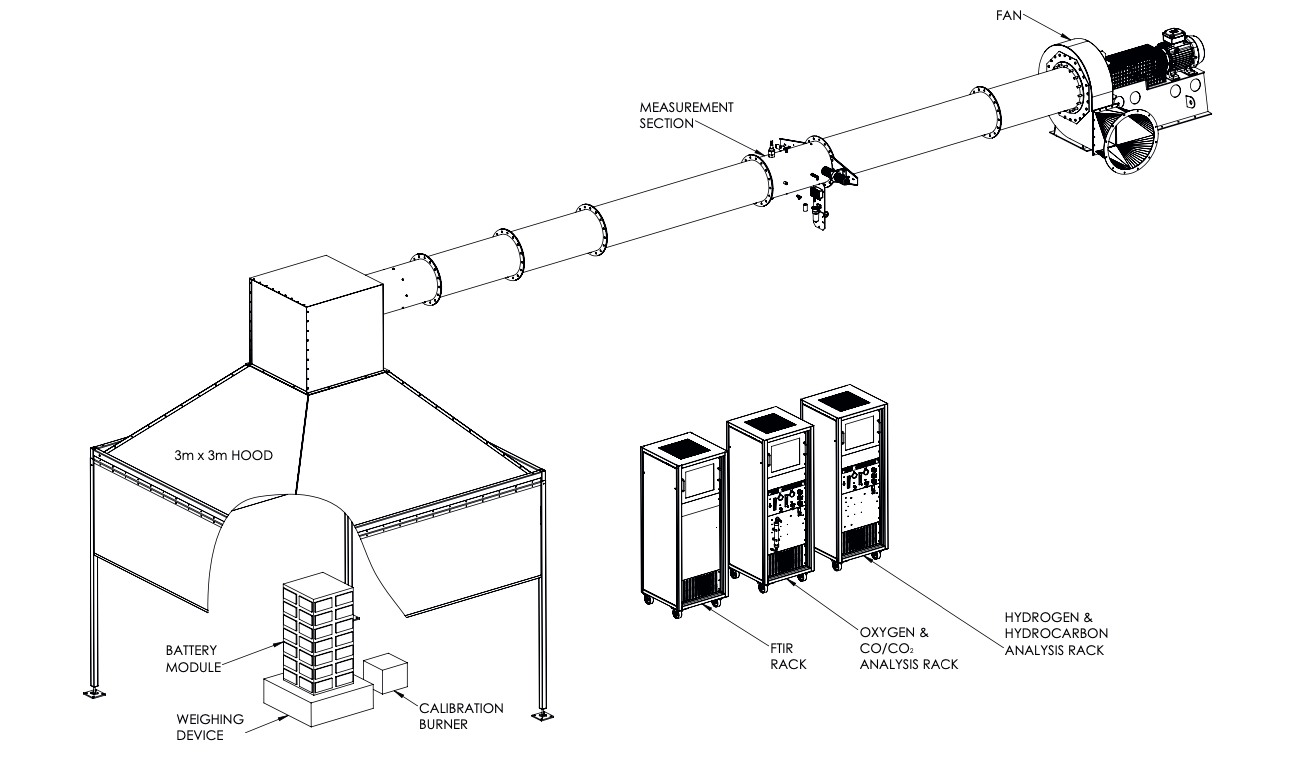

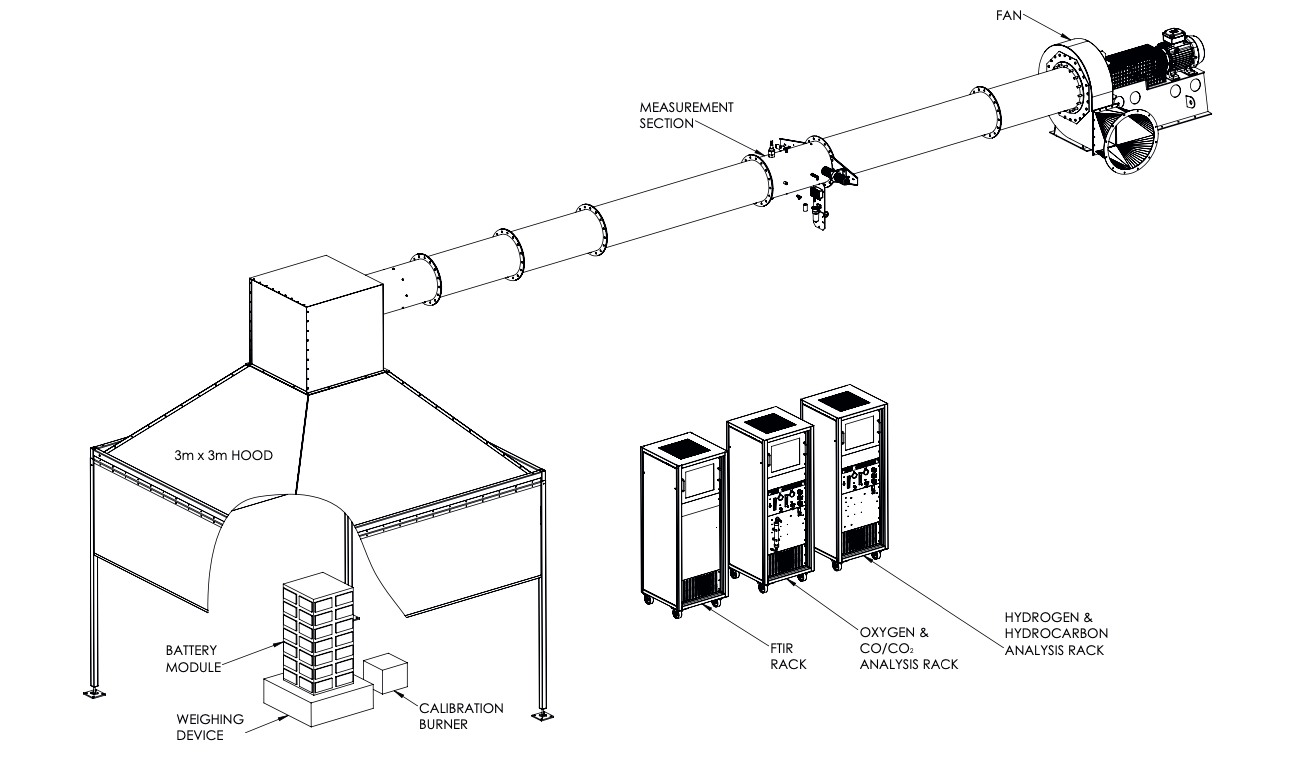

The unit level test involves heating up several cells in a battery energy storage system (BESS) to initiate thermal runaway and collecting the gaseous products under a hood and exhaust system with an internal diameter of 1.524m (in order to measure heat release rates up to 10MW). A sample of the gases in the exhaust are analysed for the concentration of oxygen, carbon dioxide, carbon monoxide and hydrocarbons as well as the composition of additional gases using FTIR. In addition the amount of smoke in the exhaust is measured using a white light smoke measurement system. The environment around the BESS is instrumented in order to measure the temperature and heat flux at adjacent walls and secondary BESS systems.

There are several parts to the Unit Level test setup:

? Heat release and smoke production instrumentation

? Instrumentation to calibrate the heat release rate system

? Extraction system

? Additional gas measurements

? Thermal runaway initiation system

? Temperature measurement systems

? Heat flux measurement system

? Convective heat release rate measurement system

The Installation Level Test

Installation level tests are only required for non-residential installations. The test configuration is similar to the Unit Level test, but does not measure the heat release and smoke production rates.

The installation level test involves heating up several cells in a battery energy storage system (BESS) to initiate thermal runaway in a room which contains a sprinkler system or other fire and explosion mitigation methods. A sample of the gases in the room is taken and analyzed for the concentration of hydrocarbons and hydrogen as well as the composition of additional gases using FTIR. The environment around the BESS is instrumented in order to measure the temperature and heat flux at adjacent walls and secondary BESS systems.

There are several parts to the Installation Level test setup:

? Extraction system

? Gas measurements

? Thermal runaway initiation system

? Temperature measurement systems

? Heat flux measurement system

Download

相關標簽

Battery, test method, energy storage, thermal runaway, 9540A, module, unit, installation

Enquiry:hkmarketing@epc.com.hk

Enquiry:hkmarketing@epc.com.hk  Whatsapp Enquiry: +85261990717

Whatsapp Enquiry: +85261990717