Description

In batch mode the product is pumped from the vacuum vessel and then returned. As it re-enters the vessel it forms a thin film over a spreader disc, offering a large surface area to the vacuum, hence releasing dissolved gases. As the product is recirculated over time, more gas is released.

When coupled to an Armfield pasteurisation or UHT system,

product can be drawn off at the rate required by the progressing cavity pump of the FT74XA or FT174X.

Product can either be drawn off until the vessel reaches its minimum limit, or the FT51 can automatically top up the vessel from an external container, using the vacuum to draw in the amount required to top up the vessel. The automatic level control maintains a max volume of approximately 10l in the vessel.

This vacuum filling mode can also be used to fill the vessel initially, prior to either batch or continuous processing.

N? gas can be introduced into the product in order to reach lower dissolved oxygen levels (down to 0.5ppm).

Some products benefit from spray deaeration and in batch mode the spreader disc can be replaced by the supplied purpose designed spray ball.

This uses multiple nozzles to produce a fine mist of product, enabling deaeration to be performed over the enhanced surface area of the small droplets.

The spray nozzle is also used in Clean-In-Place mode (CIP). This takes place under control of the Programmable Logic Controller (PLC).

The valves are switched automatically to ensure all flow paths are thoroughly cleaned.

A feature of the Armfield unit is that the UHT system can be provided with a supply of water (or product) for start-up while still connected to the FT51. Switching between the water supply and the vessel contents is quickly and cleanly achieved by a single press of the touchscreen control. Similarly when the tank is emptied or when the operator wishes to finish the run, it can be easily switched back.

Features / benefits

Enhancement of product appearance (texture, colour and/or clarity)

Preventing possible oxidation of colours, flavours, or nutritional compounds during heat treatment

Improving shelf-life by reducing in-package oxidation risks

Reducing potential usage of antioxidants in packaged products

Reducing foaming during processing and/or filling

Improving accuracy and reducing package volumes during filling

Removing dissolved gases enabling increased carbonation levels in carbonated products

Batch processing

Continuous in-line processing

Nitrogen degassing facility

Autofilling of vessel u Clean In Place (CIP) u Easy to use

Touchscreen control

– Full colour high resolution (800 x 480)

– Displays process flow diagrams and actual status

Automatic operation

Full compatibility with existing Armfield UHT systems

Controllable vacuum level

Spray or disc deaeration (batch mode only)

Integrated water feed control for ease of UHT start-up

Vacuum levels down to -0.95 bar

Deaeration capabilities of down to 0.5ppm dissolved O? (batch mode with N? degassing)

Download

相關(guān)標(biāo)簽

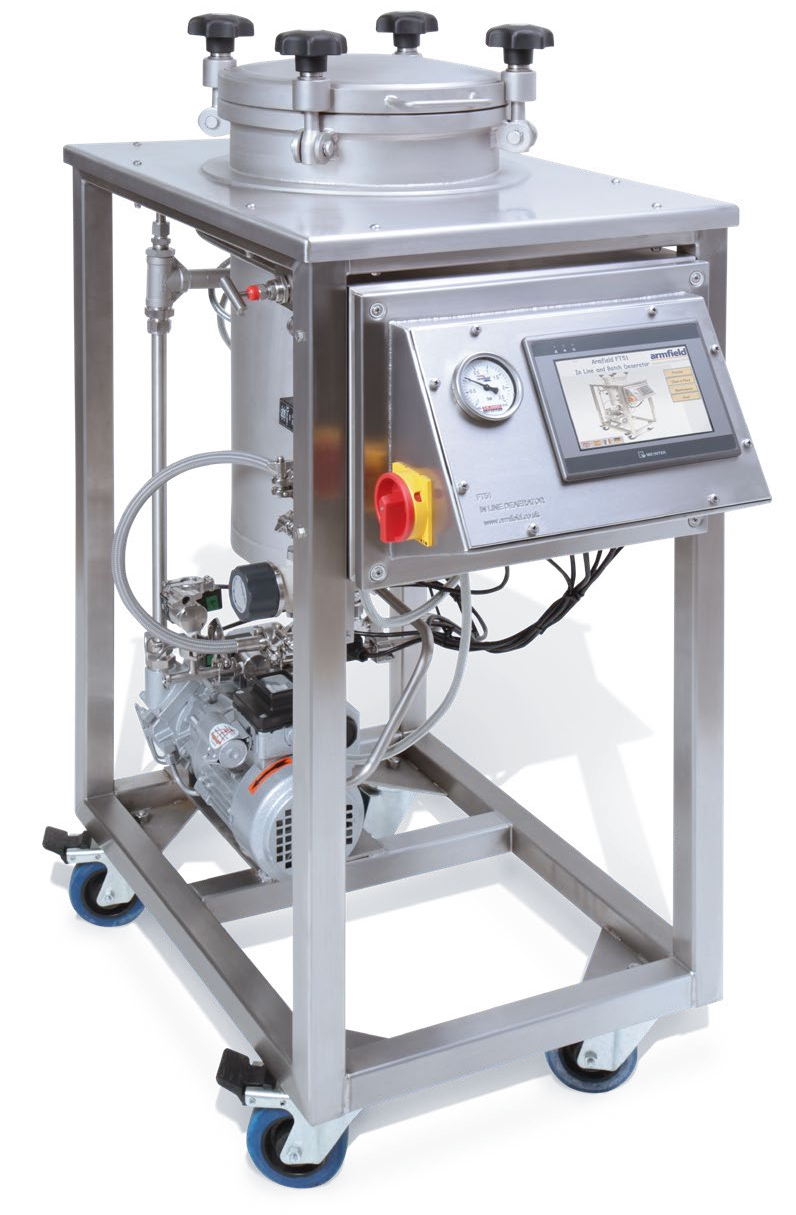

Armfield,FT51,Continuous In-line Deaerator

Enquiry:hkmarketing@epc.com.hk

Enquiry:hkmarketing@epc.com.hk  Whatsapp Enquiry: +85261990717

Whatsapp Enquiry: +85261990717